Before I got my RVA, I use to adjust preload by simply adding/removing small S/S washers on the cocking block spring guide. IIRC, they were 1/8" washers - perfect OD for hammer spring, but too small ID to fit on spring guide, so I would put 4 or 5 washers together, clamp them in a brake line flaring tool and drill them out to correct size all at once. A bit of sanding with 800 grit s-paper to smooth out the rough edges/burs and you're good to go!I shimmed the hammer spring by dropping a plastic nut and a thin washer into the the spring pocket on the rear of the hammer.

I think I'd like to try backing off on the hammer spring pre-load a little. The need for an RVA is becoming increasingly apparent.

Add a couple to guide, shoot over chrony, then add more if necessary. At a thickness of .060" per washer, you can tune velocity to pretty much whatever you want

HTH,

Todd

Reply With Quote

Reply With Quote

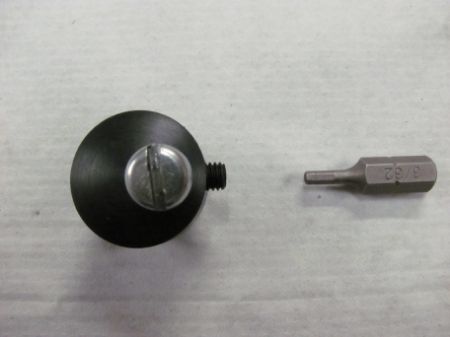

The set screw is off kilter too. I did these by hand, and it shows. I still have to figure out a way to rebate the "inside" part of the tube cap. I'm thinkin time to break out the diamond cloth again...

The set screw is off kilter too. I did these by hand, and it shows. I still have to figure out a way to rebate the "inside" part of the tube cap. I'm thinkin time to break out the diamond cloth again...

- they were too big/loose, and rolled out of the groove too easily, and ripped themselves on that first edge going into the breech. Finally got the gun to no leaks at 600-850 psi. Back up to 2200 PSI, and I'm back at the lemming leap for strings. I bet it's that hammer spring- not surprising considering all the over/under compression I've been putting it through.

- they were too big/loose, and rolled out of the groove too easily, and ripped themselves on that first edge going into the breech. Finally got the gun to no leaks at 600-850 psi. Back up to 2200 PSI, and I'm back at the lemming leap for strings. I bet it's that hammer spring- not surprising considering all the over/under compression I've been putting it through.