My poor ol' gun has gone through enough transformations, I think it has an identity crisis now!

It started out as a bone stock 2240 I purchased from Eric, but who keeps a 2240 *stock*, right?...I left it original just until I gathered up some parts for "phase 1" (which was supposed to be the only phase, btw...

) Parts included:

steel breech (with 3 barrel set screws instead of just 1)

24" barrel

2260 tube

Disco valve (modified)

Disco fill adapter

Disco hammer spring

MuzzleMack extended valve cap

Crosman shoulder stock

13 ci bottle regulated @ 1500 psi

Leapers 3-9x40 illuminated Mil Dot

couple of home brewed pieces - PA, shroud (cosmetics only), extended probe, bracket for rear of bottle.

If it wasn't for the 22xx trigger, I probably would have left it alone. I did the usual shim and polish procedure, lighter spring with guide/overtravel stop. I even did the ball bearing-on-the-lobe mod, and although it was substantially better than stock, it was still a single stage trigger with room for improvement:

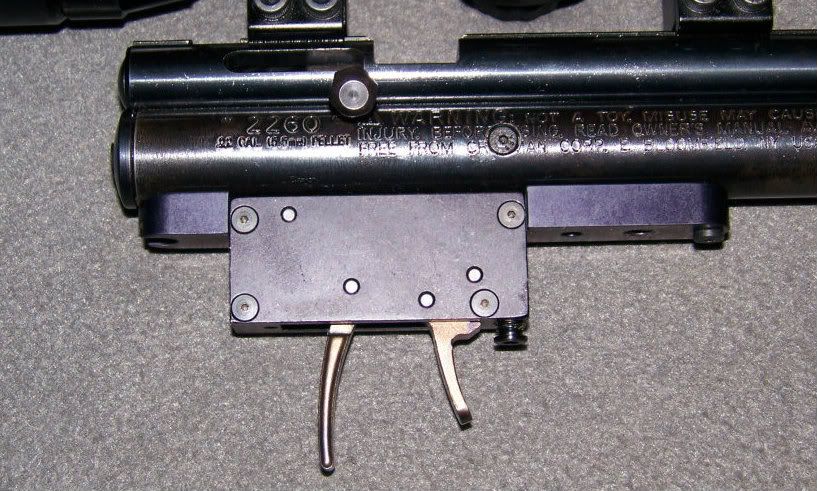

So...I got myself an M-Rod rifle trigger group and installed it, using low profile 8-32x3/8" SHCS's....OMG! I should have just done that from the start! By FAR the best trigger out of all my guns. Fully adjustable, and the 2nd stage breaks like glass. Highly recommended...The only thing with this trigger group is that you have to change the stock as you can no longer use the 22xx grip frame (unless you opt for the P-Rod trigger, and change/modify your hammer) Disco stock is a perfect fit, but I went a different route...

First, a pic of the installed trigger (no modifications needed, direct bolt-on)

I had an AR2078LE, so I purchased an "A" stock for it, and fitted the LE (thumbhole) stock to the 2260. All that was needed for it to work was to widen the slot for trigger by 1/8", and a bit of inletting so the top of trigger group sat flush with bottom of tube, as well as drilling a new hole for the stock mounting bolt. I also cut/shaped the forestock to accomodate the 13 ci bottle. By the time I had this done, I managed to put enough scratches/dings in the stock that I decided to sand it down to bare wood and re-stain. I ended up using Tung oil and Minwax "230 Early American" stain (all I had on hand), followed by 2 coats of semi gloss Diamond Wood Finish Varathane. It came out looking alright - albeit a bit *shiny* for semi gloss.

Before and after pics:

Yeah, I know - it looks a little goofy with the 3/4" space between end of bottle and stock, but seeing as front part is pretty much permanent, this is the only way I can remove bottle if/when I ever need to. Maybe I will cut a piece from the chunk I cut out of the stock and make a removeable block so it looks better ...

Other than that, I'm pretty happy with how it turned out, even if it was a lot of work just to upgrade the trigger! Worth it IMO, though...

Sorry for the long-winded post, hope you enjoy!

Todd

Reply With Quote

Reply With Quote

. For some reason I was under the assumption that only the P-Rod required the JB Weld trick. That would explain the lower velocities.

. For some reason I was under the assumption that only the P-Rod required the JB Weld trick. That would explain the lower velocities.